Poly Plow

Poly Plows are for use at slow to moderate operating speeds. Recommended for airport ramps, highways, and city streets. For Truck and Loader Mounting.

Features

- Standard. cushion valve

- Optional screw adjustable mushroom shoe assemblies

- Heavy-duty, simplified oscillating A-frame. 4″ x 4″ x 1/4″ (101.6mm x 101.6mm x 6.35mm) square tubing

- 3/8″ (9.5mm) UHMW molboard

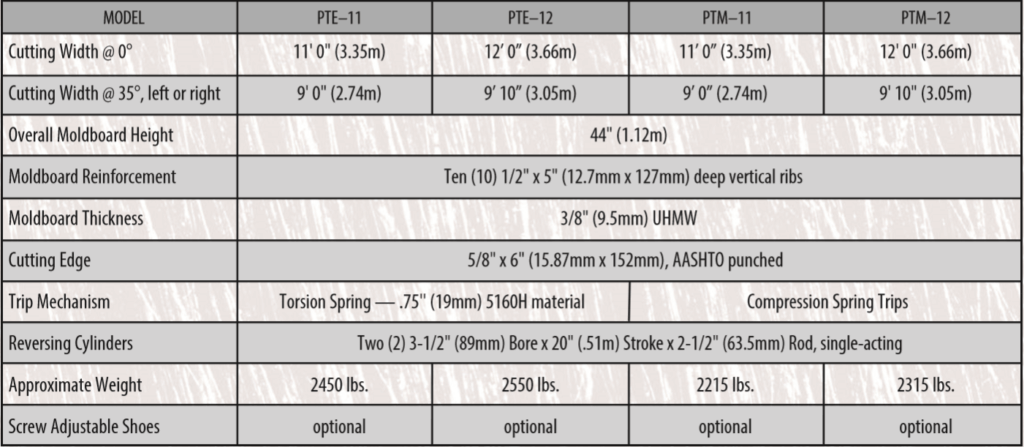

Specifications