John Deere Loader Mounted Wing

The snow-proven performance of Falls Snow Equipment is legendary and now the Falls Heavy-Duty LDL Snow Wings may be installed on a wide variety of front end wheel loaders. Get the best from your wheel loader while dealing with winter’s worst!

Features

- Streamlined, low profile design for maximum visibility

- Trip cutting edge or trip moldboard available

- Nitrogen-accumulated hydraulic push arm extension available

- Adaptable to all popular quick couplers

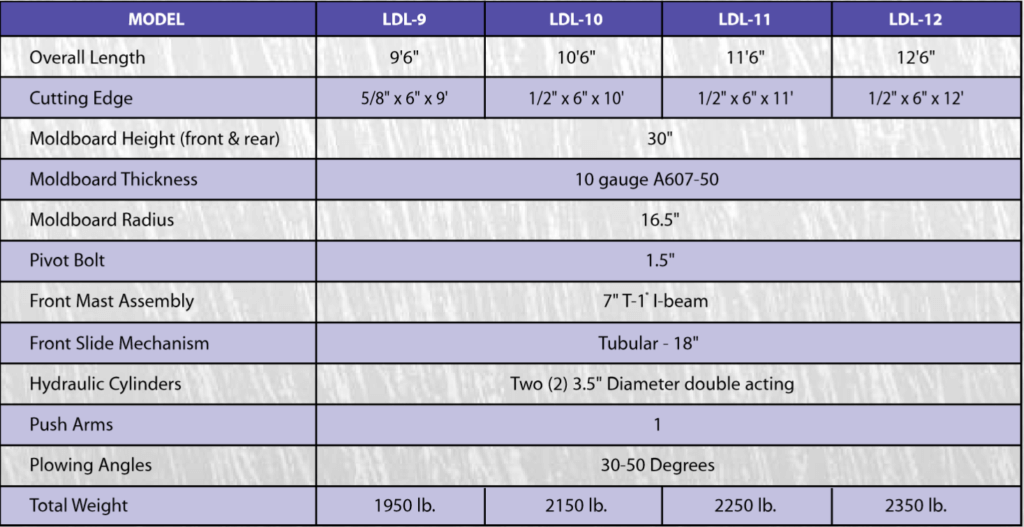

Specifications